What factors will affect the service life of the nozzle of the high pressure washer

Time:

Jul 29,2019

Author:

Source:

What factors will affect the service life of the nozzle of the high pressure washer

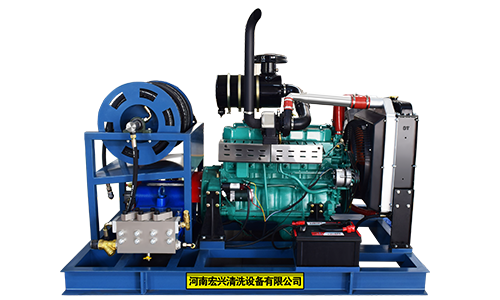

High pressure washer has become the first choice for industrial cleaning because of its high cleaning efficiency, wide application range and environmentally friendly operation. The high-pressure washing machine is the core equipment of the high-pressure water jet cleaning technology, and the nozzle is an important part of the high-pressure washing machine. Nozzle wear is a common occurrence when using a high pressure washer. Damaged nozzles can cause high pressure water jets to scatter and change direction affecting operation. What factors will affect the service life of the nozzle of the high pressure washer?

1. Self-quality: The quality of the nozzle itself also affects the length of its use. If the selected nozzle is of high quality, it will naturally take a long time. If the selected nozzle has quality problems, its use time will naturally be shortened.

2. Blockage: The continuous accumulation of chemicals and impurities inside or outside the nozzle will cause the nozzle to block. This usually affects the spray pattern of the nozzle, which in turn affects the working pressure of the pressure washer.

3. High temperature: If the nozzle runs for a long time at high temperature or abnormal temperature, the nozzle will be damaged due to the softening of the material.

4. Corrosion: When we use chemical materials to spray and clean objects, these chemicals usually cause corrosive damage to the nozzle material, thus causing safety hazards.

5. Accidental damage: For safety reasons, although the nozzle opening is usually designed to be concave, the offset structure of the fan nozzle is easily damaged if it is not used in time and maintained properly.

6. Erosion: The possibility of nozzle corrosion mainly depends on the working pressure of the high pressure washer, the type of chemical material used, the hardness of the liquid and its flow rate. In addition, particulate impurities in the liquid can also corrode the nozzle. When the high-pressure water jet flows through the metal surface of the nozzle hole, it will cause corrosion hazards to the nozzle hole, which usually causes the pressure of the high-pressure washer to drop and the spraying state to become irregular.

News Updates

—

Apr 07,2023