PRODUCTS CENTER

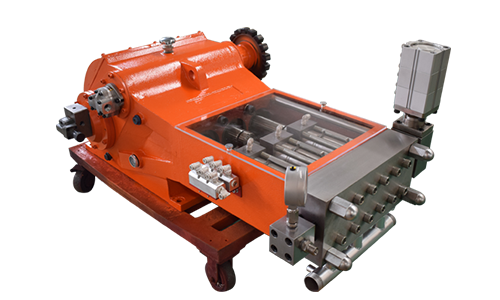

HX-3050 series (high pressure pump) has splash lubrication at the power end, stable and reliable transmission, high efficiency, stable operation, low wear and compact structure. HX-3050 series high-pressure pumps have a built-in fine-toothed gear reduction mechanism. The pump has high efficiency, stable operation, low wear and compact structure. The super-large crankcase is designed with a large amount of oil and low oil temperature, which can transport clean water, emulsion and liquids with properties similar to clean water at temperatures up to 90°C. Equipped with a pressure regulating valve (adjusting the working pressure from 0 to the maximum value), a safety valve and a relief valve (overpressure triggering and discharging to ensure safe use). The weight of a single pump is 420KG.

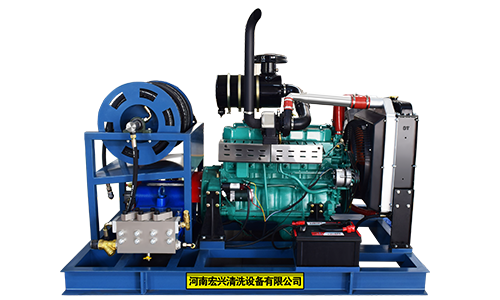

This model uses a three-plunger high-pressure pump, which is small in size, light in weight and large in flow. High-strength, corrosion-resistant forged pump head, oxidized black investment casting crankcase, hardened and finely ground crankshaft. More durable, long life, wear-resistant high-grade ceramic plunger, reinforced one-piece aluminum alloy connecting rod, U-shaped motion seal assembly, reinforced high and low pressure one-way room, higher efficiency, high-grade double-slanted needle roller bearings.

The power end of this high-pressure pump adopts herringbone gear transmission, which has stable transmission and low noise. The liquid end adopts a split structure, which is convenient for use and maintenance. The inlet and outlet valve group adopts a modular design concept, which improves the assembly process. The plunger is made of hard alloy material, which is more wear-resistant, and the seal is made of polymer combination seal to increase the service life.

The power end of this high-pressure pump adopts herringbone gear transmission, which has stable transmission and low noise. The power end is equipped with a forced lubrication system, which can meet continuous construction conditions. The liquid end adopts a split structure, which is convenient for use and maintenance. The inlet and outlet valve group adopts a modular design concept, which improves the assembly process. The plunger is made of hard alloy material, which is more wear-resistant, and the seal is made of polymer composite seal to increase the service life.